Press notes 27/08/2025

Environmentally friendly natural plastics are used to synthesise microcapsules

A URV research project has come up with a safer alternative to the toxic compounds used by industry to create microcapsules for products such as detergents

A URV research project has come up with a safer alternative to the toxic compounds used by industry to create microcapsules for products such as detergents

Widely used in many products (cosmetics, food, pharmaceuticals and especially detergents) microencapsulation consists of retaining an active ingredient within a tiny container for a certain period of time until it is released. In the case of detergents, microcapsules are used to retain active ingredients such as bleaching agents or fragrances and to release them in a controlled manner during the washing cycle through the action of external influences such as water, scrubbing or pressure. Once they have fulfilled their function, the empty capsules pose a problem insofar as they are toxic, non-biodegradable and can represent a health risk.

Traditionally, these tiny containers are synthesised with polymers derived from formaldehyde, a chemical known for its harmful effects on the body. If they remain on our clothes, they come into direct contact with our skin. If, on the other hand, they are carried off in water from the washing machine, they end up in sewage treatment plants which, unable to filter them, release them again downstream until they reach the sea where, inevitably, they enter the trophic chain, of which we humans are the last link. Regulatory bodies such as the EU with its regulations on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) are aware of this problem and are already preparing measures to restrict these microplastics. Furthermore, researchers from the URV’s Department of Analytical and Organic Chemistry and Department of Chemical Engineering are working to provide a biodegradable and safe alternative.

Biodegradability and resistance

What they are proposing are double-layer capsules made from alginate and PEGDA, two substances that combine biodegradability with resistance. Alginate is a natural polymer extracted from Mediterranean brown algae. It is a renewable and abundant material that stands out for its ability to gel and form biodegradable polymeric networks. However, capsules made exclusively from alginate are not strong enough to withstand the demanding conditions of industrial processes or the mechanical forces and pressures of transport. To increase their robustness, a network is formed by combining alginate with PEGDA, a synthetic but biocompatible polymer that can interact with a biological system without causing damage and which provides the alginate with thermal and mechanical stability.

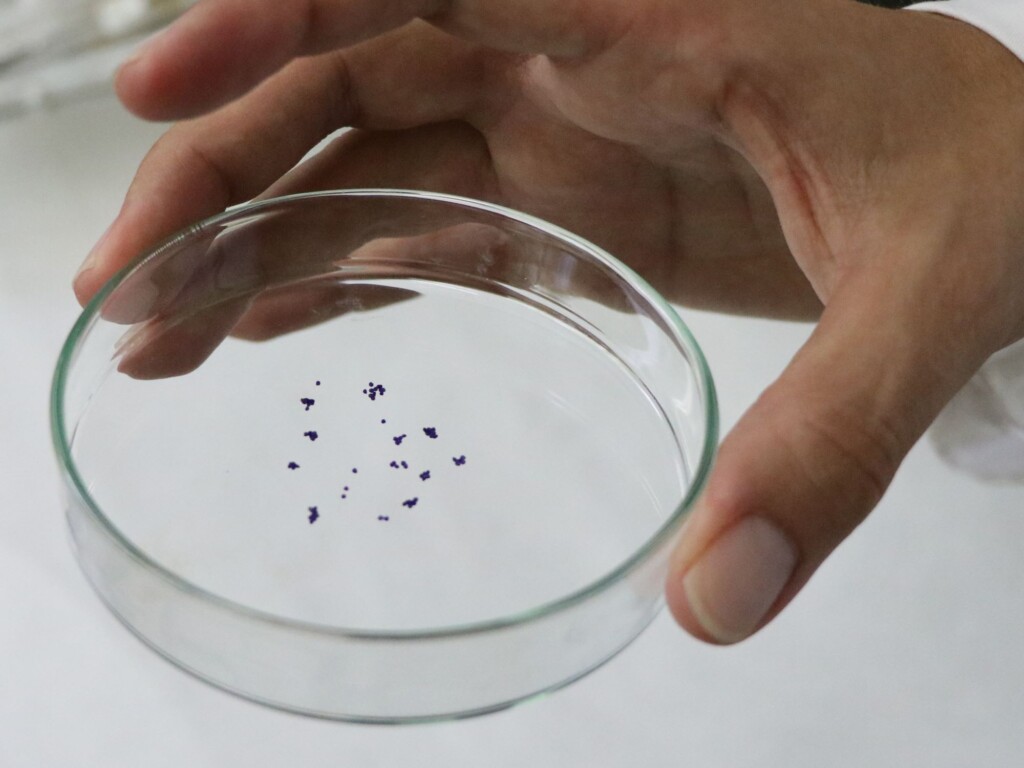

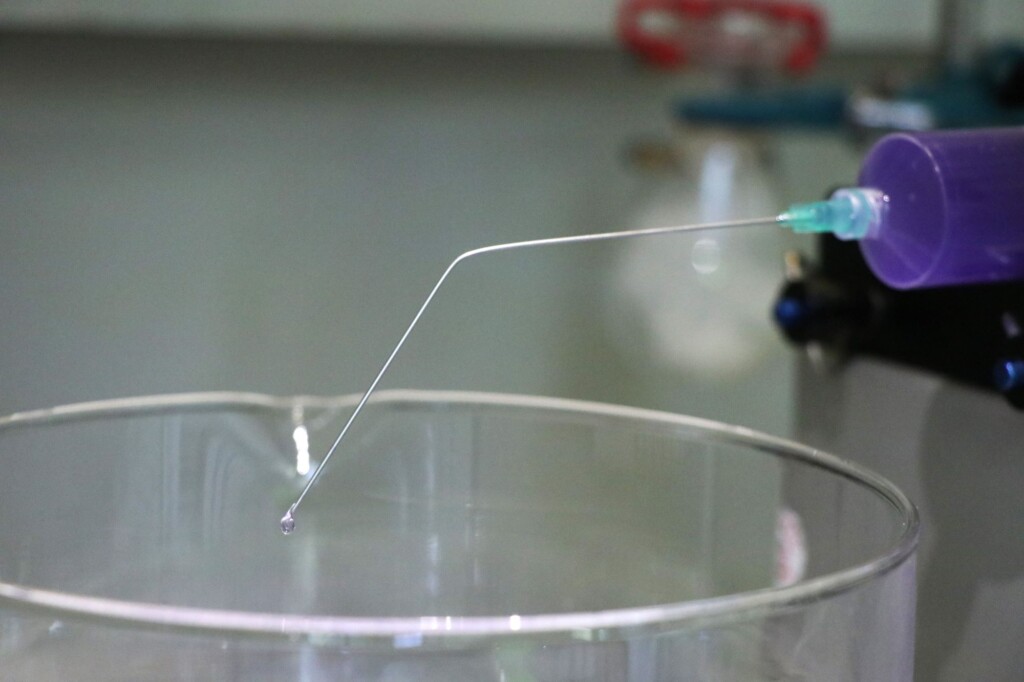

The manufacturing process of these capsules is simpler – and more aesthetic – than one might expect. It starts with an aqueous solution containing the active ingredient – in this case a blue dye – and alginate and PEGDA molecules, which are placed in an extruder, i.e. a mechanised syringe. The extruder plunger pushes the solution through a curved needle so that it falls, drop by drop, into a constantly agitated calcium chloride bath. Once the drop enters the bath, the calcium ions from the solution join the alginate molecules on the outside of the drop, causing them to gel. The result is a sphere that encapsulates the product.

Once the first layer has been formed, the research team exposes the bath – full of soft microcapsules rotating in circles due to constant agitation – to ultraviolet light for five minutes. This radiation causes the PEGDA to polymerise and combine with the gelled alginate to form a network that gives greater solidity and cohesion to the capsules. By controlling various parameters in this process, such as the pressure from the extruder plunger, the diameter of the needle or the concentration and temperature of the solutions, it is possible to modulate the size and properties of the resulting capsules. In this study, the capsules obtained had a diameter of just over one millimetre.

Surprising results

To determine their properties, the research team subjected the capsules to a battery of tests, a kind of quality control, which revealed some surprising results.

One of the things they paid most attention to is the chemical stability of the capsules. When a certain substance – in this case a polymer – is synthesised by means of a chemical reaction, it is important to make sure that the resulting material has reacted completely. If this is not the case, and the polymer in the capsules is not completely inert, it could react on contact with the skin, for example, producing potentially harmful or irritating by-products. In this regard, one of the main improvements of the study was the use of a similar but less reactive plastic, PEGDA, instead of PEGDMA. PEGDA allowed the research team to synthesise more chemically stable capsules and minimise the presence of residual compounds.

In addition to chemical stability, PEGDA has demonstrated other qualities, for example, in mechanical resistance. Tests revealed that the Young modulus – a parameter that describes the rigidity of the material – and the breaking strain were sufficient to withstand industrial processing and transport without breaking. Although they are deformable, their elasticity prevents them from fracturing and releasing their contents before they are needed. “We need to design very finely balanced capsules: we need them to have the necessary stability to withstand the production and post-production phase but, at the same time, we need them to be able to break down when necessary,” explained Xavier Montané, a researcher at the URV’s Department of Analytical and Organic Chemistry and co-author of the research.

In addition to the properties of the capsules, the research team highlighted the advantages of the manufacturing process. Thanks to its relative simplicity, it is easily scalable to industrial environments and allows the continuous production of capsules, in a kind of industrial chain: “The extrusion process is simple, cheap and scalable; these qualities, together with the properties of the capsules, make it an attractive alternative with great potential for industry,” says Marta Giamberini, a researcher at the URV’s Department of Chemical Engineering and co-author of the research.

More research

Despite the success of the initiative, the research team believe that the method needs to be further developed to explore its full potential. One of the immediate priorities is to carry out exhaustive studies on the biodegradability of these compounds; that is, to determine precisely the extent to which they decompose and under what conditions. These tests are essential in order to obtain the certifications necessary for them to enter the market.

Further research will also involve combining alginate with other natural polymers that would guarantee the total biodegradability of the capsules while maintaining their physicochemical properties. This would pave the way for other sectors such as the pharmaceutical and food sectors to benefit from this improved technology, which is completely plastic-free, biocompatible and environmentally friendly.

Reference: Kabalan, Y., Tylkowski, B., De La Flor, S. et al. Synthesis and characterization of biobased capsules formed from interpenetrating networks of alginate and poly(ethylene glycol) for the encapsulation of blue dye. Sci Rep 15, 22215 (2025). https://doi.org/10.1038/s41598-025-05352-y